Gampa Alcoats Ltd. (GAL) has been an established manufacturer of Metallized paper, film and board in India since 1987. With over 30 years of service to the flexible packaging industry and a monthly production of 300MT, there is a constant upgradation of machinery and R&D to provide improved and superior grade products.

GAL was established by Mr. Ashok Kumar Gampa with a vision to provide the finest quality product with everlasting benefits to the packaging industry. At GAL we believe in expanding our horizons and work on diversifying our products to venture new markets, with state of the art machinery. Our developmental plans are moulded with ideas to benefit the customer with the finest technology and sustainable practices. A harmonious workforce of over 50 employees has helped shape the industry to its current stature.

To be the leading producer of high quality metallized products for companies globally, with focus on development of sustainable and environment friendly products.

At GAL we use a direct metallization technique, the process of metallizing involves depositing a very thin metallic coating onto paper by vaporizing aluminum in a vacuum chamber and allowing the metal to condense onto the substrate. Before and after this deposition, the substrate is coated with highly technical lacquers.

Metallized papers offer a solution to achieve the distinctive metallic finish with only a fraction of the aluminum content of traditional foils. Using a foil or metallic inks to achieve this look creates environmental burdens due to the high percentage of aluminum in the packaging structure. Also metallic films creates a heavy ecological impact.

High-end brands upgrade to more appealing and engaging designs and boost their notice on the shelf by using metallic surfaces. The materials remain compostable - similar to paper.

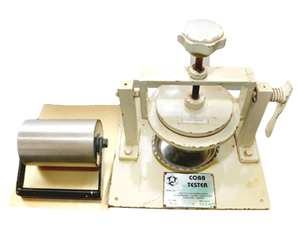

GAL manufacturing unit in Bidar houses a Laboratory and research unit where in our team of experts have tirelessly developed and improved the products with frequent testing and analysis using modern equipment to produce high quality product.

The manufacturing facility is located in Bidar district of Karnataka, in honour of our founders ancestral origins. GAL has state of the art machinery sourced from leading producers in Europe. In a working area of over 8 acres with new and improved coaters, metallizers and slitters, the facility is environmentally conscious and reduces pollution or waste to minimal.

GAL specialises in metalizing a variety of substrates such as paper, board and films etc. We also undertake speciality orders on request as per customer requirement, to mutually develop the product along with the customer.

| Metallised Paper | Grammage (GSM) | Applications |

|---|---|---|

| Poster | 35-70 | Inner liners for Cigarette Packaging |

| Maplitho | 54-80 | Inner liners for Cigarette Packaging |

| Chromo w/wo wet strength | 70-90 | Liquor, Beer, Pharmaceutical Labels, Stickers, Gift Wrappers etc. |

| Art Paper | 80-150 | Decorative and Gift Wrapping |

| Cast Coated | >85 | Labels for premium products, gift wraps, Liquor labels Soft labels for confectionery, Ice creams and food products |

| Metallised Board | Grammage (GSM) | Applications |

|---|---|---|

| White Back | 150-300 | Garment Boxes, Book Covers |

| Pulp Board | 150-300 | Folding Boxes, Beverage Carriers |

| Duplex Board | 150-300 | Garment Boxes, Agarbathi Packets, Pharmaceutical Boxes |

| Grey Back | 150-300 | Agarbathi Packets, Pharmaceutical Boxes |

| Cast Coated Board | 150-300 | Liquor Cartons, FMCG Packets |

| Coated Grey Back | 150-300 | Folding cartons, Beverage Carriers, Book and Report Covers, Mailing Tubes, and Cassette boxes |

| Coated Folding Box | 150-300 | Cigarette Boxes |

| Art Board | 150-300 | Book Covers, Decorative Boxes |

| Metallised Film | Thickness (micron) | Applications |

|---|---|---|

| PET | >10 | Flexible Pouches, Peel-able Seals, Snack Packs, barrier films, Can Laminations and Vacuum Insulation panels |

| BOPP | >15 | High barrier performance sandwich layer, Decorative & general purpose, Packaging, Lamination & Decorative, Label application |

| BOPET | >10 | Flexible Packaging, Food Packaging, Graphic Art |

| CPP | >12 | Food Packing, Barrier & Decorative, Candy Wrapping |

Note:

1. All products come with optional print receiver coat (OPV).

2. All products are manufactured using direct vacuum metallization.

3. Width and Length of the roll, as per customer requirement.

4. The end product can be supplied in Matte/Gloss finish.

5. Additional specifications can be incorporated based on customer requirement.

Metallized paper for cigarette packets inner liners, for both soft and crush proof packaging

The Metallized paper meets all the quality standards set by the customer, additionally it shows excellent run-ability properties on all packaging machines at various speeds. The paper is durable, shows very good folding properties and low coefficient of friction. The paper does not produce any dust while packaging, therefore cigarettes are not contaminated. The product is odour free and tasteless as its base coat is water based and does not contain toxic substances.

The main characteristics when it comes to beverage labels are wet strength, glueability on wet surface, alkali resistance, high dimensional stability, wet strength, printability and high gloss, which are present in Metpa L. Metallized paper meets all the quality standards set by the customer. Metpa L is extensively tested for taste and smell and it shows no traces of it. The paper does not produce any dust while packaging, therefore contents in the packing are not contaminated. The product is odour free and tasteless as its base coat is water based and does not contain toxic substances.

GAL has a never-ending commitment to improve and develop the product in order to satisfy customer needs. We are an ISO 9001: 2015 & 14001: 2015 certified company. GAL gives utmost importance to quality and environmental safety, therefore audits are conducted and certification is obtained on a regular basis. With near-zero pollution, we adopt the best of systems for process and quality control which helps in continuous improvement.

Our Quality policy is to produce quality products for packaging at competitive prices to enhance consumers satisfaction and product aesthetics through team work and continual improvements of quality management systems.

GALs policy is to carry out coating process in a manner that is not detrimental to the environment or safety or the health of our people and community at large, with tireless commitment to:

● Prevention of Pollution

● Controlling Land Pollution

● Complying with regulations

● Continual improvement of our EMS system

Get in touch with us

Corporate Office:

2nd Floor, 6-2-982, Khairatabad,

Hyderabad, Telangana,

India - 500004

Manufacturing Unit:

12(A), Kolhar Industrial Area,

Bidar, Karnataka India - 585403

info@gampaalcoats.com